-

UPPER/OUTSOLE BOND STRENGHT TESTUpper/Outsole Bond Strength (Whole Footwear) (EN ISO 20344:2011(5.2))

-

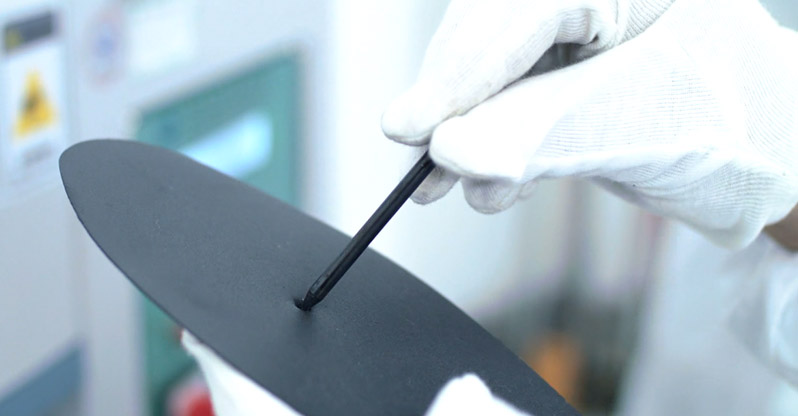

ANTISTATIC TEST

-

COMPRESSION&PUNCTURE TESTEN 12568:2010 1-Corrosion Resistance Of Metal Penetration Resistant Insert (BS EN 12568:2010, 6.3.2 & 7.3, 1% NaCl Solution, 48 Hours) 2-Nail Penetration Resistance Of Penetration Resistant Inserts (BS EN 12568: 2010,6.2.1 & 7.2.1, 10 mm/min) 3-Multiple Flex Resistance Of Penetration Resistant Inserts (BS EN 12568:2010, 6.2.2 & 7.2.2)

-

ANTI IMPACT TESTEN 12568:2010 1-Impact Resistance Of Toe Caps (EN 12568:2010, 4.2.3, Energy Level: 200 Joules) 2-Compression Resistance Of Toe Caps (EN 12568:2010, 4.2.4, Compression Load: 15 kN) 3-Corrosion Resistance Of Metal Toe Caps (EN 12568:2010, 5.3, 1% NaCl Solution, 48 Hours)

-

ANTI YELLOWING CF TO LIGHT TEST

-

Abrasion Resistance For Outsole

-

BENDING TEST OF FINISHED SHOESFlexing Resistance (Outsole) (EN ISO 20344:2011(8.4))

Product capacity: 100000 pairs per month

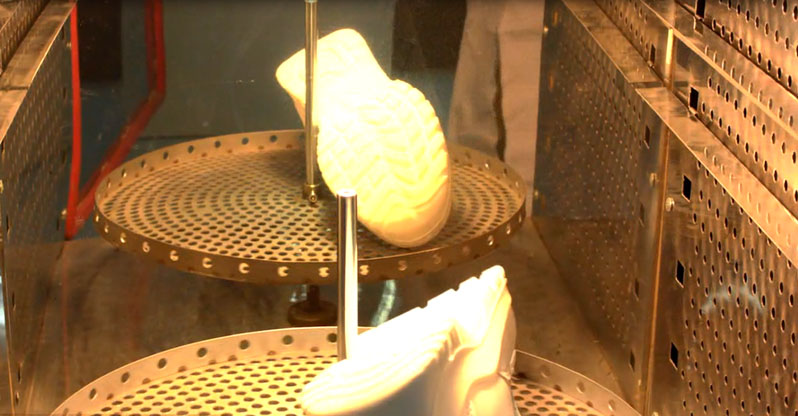

Outsole technology: PU/PU,PU/TPU,PU/RUBBER,Eva/Rubber,Rubber...

Development: 2-3 new outsole per year for the market.

Price and quality: Low market price and guarantee time 8-10 months.

Delivery time: Fast 15 days after confirming the order

Main customer: UK-Black hammer, Black rock, Italy: U-power, Beta, South America: Tempest, South Africa: DOT.